| 1.All the moldbase steel and dimension per DME standard |

All the steel and dimension of inch moldbase per DME catalouge specification,the metric mold base per HASCO :

1.1 #1 Moldbase:all plates AISI 1050,13~18 HRC.

1.2 #2 Moldbase:A plate,B plate and E.J. plate:AISI P-20,28~32 HRC.strength900N/mm2

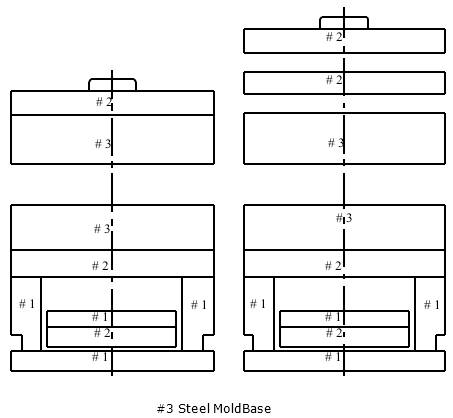

1.3 #3Moldbase:A plate,B plate:AISI P-20 modified,32~36 HRC,good polishability and machinability.

1.4 #7 Moldbase:A plate,B plate and plates with waterlines :preharden AISI 420H,33~37 HRC(strength915~1200N/mm2),other plates:per #2 Moldbase.

1.5 The hot runner mold per above requirement and the hot manifold must be AISI P-20 modified,32~36 HRC if it is selfmade.

| 2. Preferred moldbase dimension: |

Notes: :

1.Stress relief A & B plate after the pocket for cavity and core block rough machining;the lead pins holes should be machined after all other item completed;

2.the above dimension based on #2 steel (28~32HRC,915N/mm2), correction should be made for severe application;

3.radius RA and RB per standard tool diameter;

| 3. Machining items when ordering moldbase: |

Try machine as many items as possible to minimize the heat distort when the subsequent machining is processed, the following items should always be tried and completed at mold base supplier:

- the pocket for cavity and core block

- the pocket for the straight side lock

- the pocket for the tapper side lock

- the pocket for the cycle counter

- the pocket for locating ring

- the pocket for sprue bushing

- the pocket for support pillar

- the pocket for spring of return pin

- the knock out hole

- the pocket for slide and it’s clearance

- the pocket for the balanced block

- the clearance for the angle pins if needed

- the pocket for hot runner system

- the pocket for gear and rack system in unscrewing mold

- the pocket for round cavity and core block

- the water lines in mold base